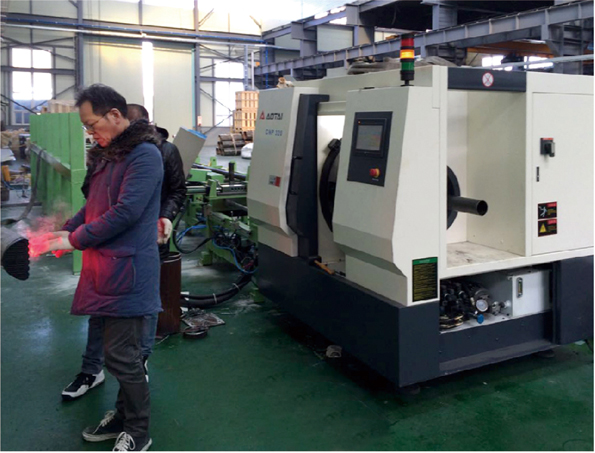

CNP HIGH SPEED PIPE CUTTING AND BEVELING MACHINE

AOTAI CNP series High speed pipe cutting and beveling machine is a kind of efficient pipe cutting and beveling prefabrication CNC machine.designed to cut, bevel, single point on the pipe with high speed. considerable heavy wall and for any type of material.

Range for pipe OD:50-914mm

OVERVIEW

AOTAI CNP series High speed pipe cutting and beveling machine is a kind of efficient pipe cutting and beveling prefabrication CNC machine.designed to cut, bevel, single point on the pipe with high speed. considerable heavy wall and for any type of material. Adopt servo motor drive, with AOTAI CNC system, double hydraulic clamping system, self-centering system. and pipe length setting system and pipe conveying system are optional. This series machine advantage with high speed, high precision, high quality of cutting, easy to control. it is the key equipment for all kinds of pipe prefabrication. suitable for cutting and processing pipe of oil, chemical, natural gas, nuclear power and other industry.

FEATURES

1、4 models are available in pipe OD:50-914mm

2、Cold cutting, don’t influence the pipe’s material

3、High speed cutting, feeding control by program

4、Machine up/down design, and control by program

5、Exclusive CNC system, make everything become easier.

6、Built-in water cooling systems, increasing the life of machine and tools.

7、Both front and back hydraulic clamping system, self-centering, precision solid.

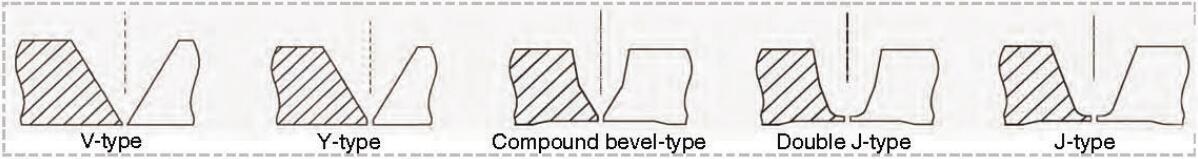

8、Varity of beveling shape: “U”,“V”,“J”, double “V”, compound bevels.

9、Cutting and beveling,and can be used for cutting, beveling, double beveling.

10、Independent servo motor driven, can realize feed and retract with correlation, differential, independent.

CAPABILTY

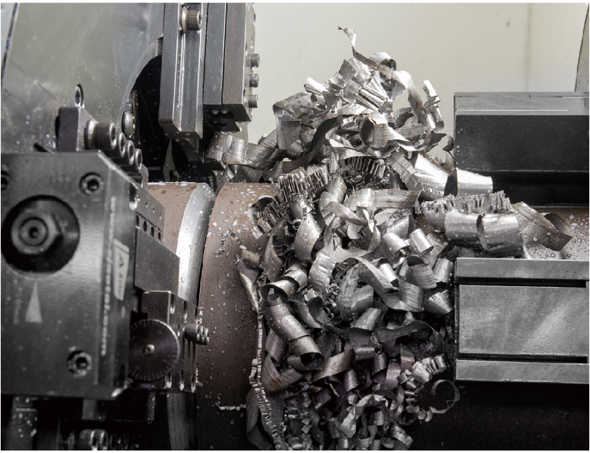

1、Pipe cut off

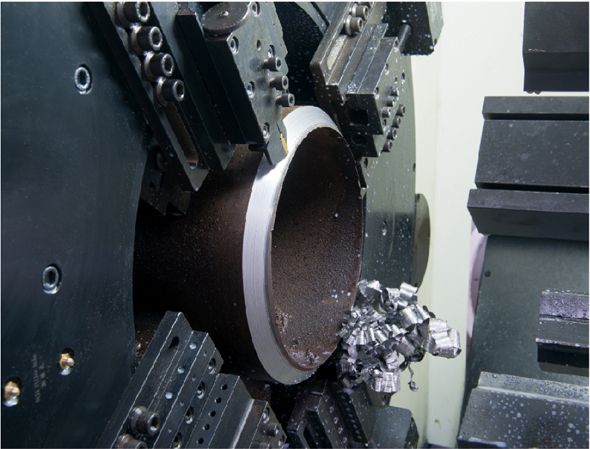

2、Pipe end beveling

3、Pipe facing

4、Cutting and beveling

5、Compound beveling

6、Counterboring

7、Grooving

BEVELING SHAPE

*other beveling shape, angle and pipe material, please declare before order

|

Model |

Working Range |

Wall Thickness |

Rotating |

Motor Power |

||||

|

OD mm |

Single mm |

Multi mm |

rpm |

Cutting |

Clamping kw |

Up/down kw |

Feeding kw |

|

|

CNP-320 |

50-320 |

4-25 |

50 |

0-50 |

5.5 |

1.5 |

0.55 |

2.0 |

|

CNP-450 |

130-450 |

5-25 |

50 |

0-42 |

7.5 |

1.5 |

0.55 |

2.0 |

|

CNP-610 |

323-610 |

5-25 |

50 |

0-35 |

11 |

1.5 |

1.5 |

2.0 |

|

CNP-914 |

610-914 |

6-25 |

50 |

0-25 |

11 |

1.5 |

2.0 |

3.0 |

Above parameters just for reference only, not acceptance criteria

Power requirement:380V,50-60Hz,3P

Up/down travel:200mm

pipe length limit:300mm

Tool post quantity.:2 or 4

Angle deviation:±0.5

Vertical deviation:±0.5mm @300mm pipe OD

Insert Type

Tool holder:40Cr

Insert:CSS or Carbide

kinds:Cut off,beveling,Double beveling,Compound beveling

Angle:0°,30°,37.5°,double 30°/37.5°,37.5°+10°

OPTION PIPE CONVEYER

According to the need to customize.

Optional pipe conveyer and automatic length setting systems, be formulated with highly efficient logistics system, and form

pipe cutting and beveling prefabricated production line

*Customizable size and option the automatic or manual feeding.

|

Input pipe conveyer |

Output pipe conveyer |

|

|

| Length setting system | Exchange system |

|

|

|

Cutting and Beveling |

Pipe end Beveling |

|

|

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

CND Stationary pipe cutting and beveling machine

AOTAI CND Stationary pipe cutting and beveling machine is a practical and durable pipe cutting beveling machine. It was developed cutting and beveling for pipe prefabrication. Adopt variable frequency motor drive, electric clamping system, self-centering system. automatic feeding

Learn MoreKSD Portable-bench pipe cutting and beveling machine

OSD/KSD Portable-bench pipe cutting and beveling machine is a portable and bench machine. It was developed cutting and beveling for pipe prefabrication. The main machine can be fixed on the bench in workshop, and it also can be used to field cutting and beveling with option our car type bench.

Range for pipe OD:20-720mm

OCD High speed pipe beveling machine

This series of beveling machine tools were developed aims at large quantities of pipe end beveling processing,It is new equipment of pipe prefabrication. Bevel pipe fast, auto-center hydraulic clamping system, can match main machine auto-up/down system to suit different diameter pipes to use, suitable for bevel processing of all kinds of carbon steels, stainless steels, alloy steels, etc. Can bevel different types of shape according to customer’s requirement: U, V, J, Y, X,etc. excellent quality of beveling, efficient working, easy to operate.

OCF- CNC Pipe Beveling Machine

OCF was developed pipe end beveling High speed,It is new equipment of pipe prefabrication.It adopt SIEMENS CNC system, hydraulic clamping , machine up/down. It process different types bevel shape according to customer’s requirement: beveling U, V, J, Facing ,Counter-boring,etc.

Learn More