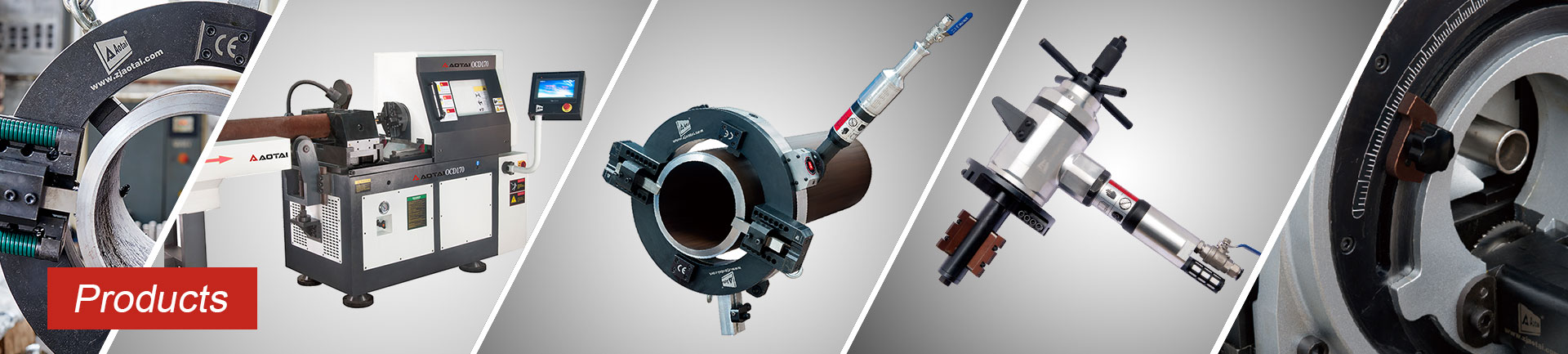

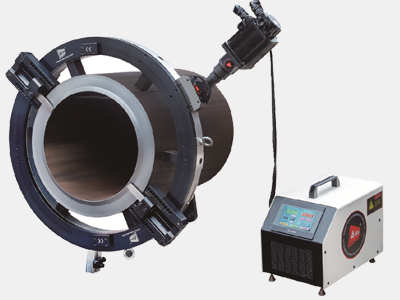

Standard split frame pipe cutting and beveling machine

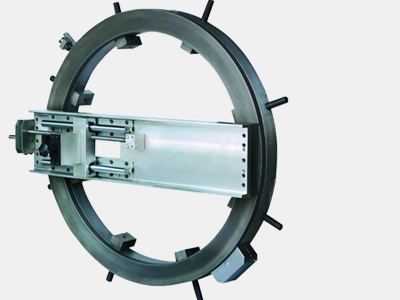

Aotai Standard split frame machine, designed to cut, bevel, single point, counterbore and face on the pipe, tube and flanges. It is a portable pipe cutting and beveling machine tools of clamshell style. smartly designed, ability to split in half at the frame, easy to install on the pipe line.

Range for pipe OD 1"-48"

OVERVIEW

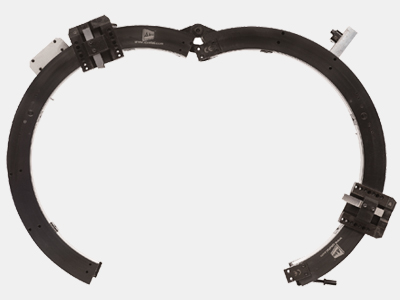

Standard split frame pipe cutting and beveling machine, designed to cut, bevel, single point, counterbore and face on the pipe, tube and flanges. It is a portable pipe cutting and beveling machine tools of clamshell style. smartly designed, ability to split in half at the frame, easy to install on the pipe line. It is comprehensive used in pipework of oil, gas, food, petroleum, chemical, boiler, medicine machine, nuclear power, and power supply construction. 16 models are available in 6 inch (152.4mm) increments, with additional sizes available by special order.

Features and Advantages

1、16 models, Working range for pipe OD 1”-48”

2、Non-standard model can be customized

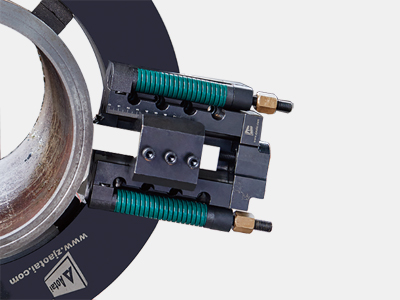

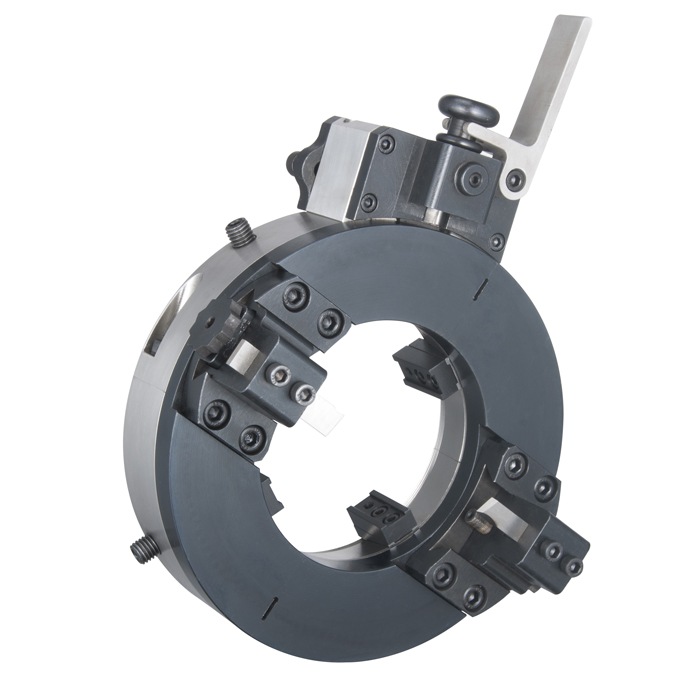

3、Out-mounted style, clamping by multipoint jaws.

4、Split frame technology, easy to install on the pipeline.

5、Cold cutting and beveling, don’t influence the pipe’s material.

6、Auto feed, cutting and beveling at the one time, cost effective.

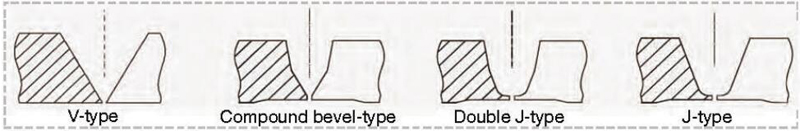

7、Varity of beveling shape: “U”,“V”,”Y“,J”, double “V”, compound bevels.

8、Stationary ring is steel; rotation ring is aluminum, and steel optional

9、Electric. pneumatic, numerical controller and hydraulic drive options are available.

10、Several different drive options are available to best position the motor for a specific machining application.

11、It can be equipped a wide range of accessories to increase performance and expand capabilities.

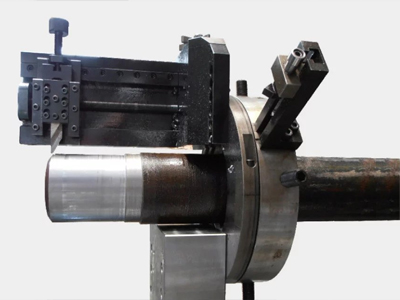

CAPABILTY

1、Pipe cut off

2、Pipe end beveling

3、Pipe facing

4、Cutting and beveling

5、Compound beveling

6、Counterboring

7、Flange facing

8、Grooving

BEVELING SHAPE

*other beveling shape, angle and pipe material, please declare before order

| Model | Pipe Capacity OD | wall Thickness | Rotating | |||||

| Electric | Pneumatic | NC | Hydraulic | mm | inch | mm | rpm | |

| ISD-90 | ISF-90 | SKD-90 | HYD-90 | Ф20-90 | 3/8"-3" | 30 | - | 34 |

| ISD-168 | ISF-168 | SKD-168 | HYD-168 | Ф25-168 | 1"-6" | 30 | 50 | 24 |

| ISD-219 | ISF-219 | SKD-219 | HYD-219 | Ф50-219 | 2"-8" | 30 | 50 | 23 |

| ISD-273 | ISF-273 | SKD-273 | HYD-273 | Ф114-273 | 4"-10" | 30 | 75 | 23 |

| ISD-323 | ISF-323 | SKD-323 | HYD-323 | Ф168-323 | 6"-12" | 30 | 75 | 23 |

| ISD-355 | ISF-355 | SKD-355 | HYD-355 | Ф177-355 | 8"-14" | 30 | 110 | 23 |

| ISD-406 | ISF-406 | SKD-406 | HYD-406 | Ф254-406 | 10"-16" | 30 | 110 | 22 |

| ISD-457 | ISF-457 | SKD-457 | HYD-457 | Ф323-457 | 12"-18" | 30 | 110 | 20 |

| ISD-508 | ISF-508 | SKD-508 | HYD-508 | Ф355-508 | 14"-20" | 30 | 110 | 20 |

| ISD-559 | ISF-559 | SKD-559 | HYD-559 | Ф406-559 | 16"-22" | 30 | 110 | 14 |

| ISD-610 | ISF-610 | SKD-610 | HYD-610 | Ф457-610 | 18"-24" | 30 | 110 | 14 |

| ISD-762 | ISF-762 | SKD-762 | HYD-762 | Ф610-762 | 24"-30" | 30 | 110 | 13 |

| ISD-914 | ISF-914 | SKD-914 | HYD-914 | Ф762-914 | 30"-36" | 30 | 110 | 11 |

| ISD-1066 | ISF-1066 | SKD-1066 | HYD-1066 | Ф914-1066 | 36"-42" | 30 | 110 | 10 |

| ISD-1160 | ISF-1160 | SKD-1160 | HYD-1160 | Ф980-1160 | 38"-44" | 30 | 110 | 9 |

| ISD-1240 | ISF-1240 | SKD-1240 | HYD-1240 | Ф1040-1240 | 40"-48" | 30 | 110 | 9 |

POWER SUPPLIES

|

Electric: Convenient power supply Stable Performance Popular choice Electric requirement:220-240V 1PH 50/60HZ Carbon brush Motor:1.43KW,1.7KW,2.4KW Brushless Motor: 1.5KW,2.0KW,3.0KW Double motor for big model or heavy duty |

Pneumatic: Explosion Proof Stable Performance Easy to maintenance Air requirement:1500-2000L/min @0.63-0.8Mpa Power:2HP,3HP,4HP Double motor for big model or heavy duty |

|

|

|

NC: Powerful drive, High efficiency Low noise ,Stable Performance Ideal for heavy wall thickness & large size pipe Electric requirement: 230V 1PH 50/60Hz; 380V 3PH 50/60Hz Power:2.0KW or 3.0KW Double motor for big model or heavy duty |

Hydraulic: Powerful drive, High efficiency Stable Performance, Low noise, Anti-explosion Ideal for heavy wall thickness & large size pipe Hydraulic requirement:28-50L/min @13Mpa Electric requirement: 380V 3PH 50/60Hz Rated Pressure:13MPa Rated flow:28L/min Max.Torque:380NM |

|

|

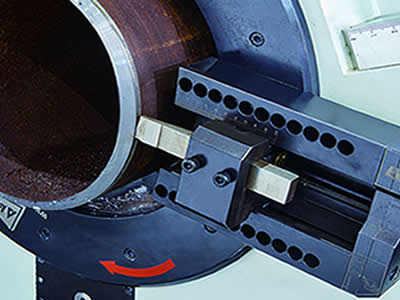

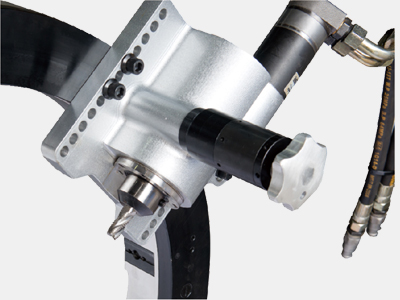

TOOLING

Form Style and Insert Style

HSS, HSS Co, Carbide

Make more tooling on demand

|

Form Style Material:M42 and M35 Type:Sever,bevel,double bevel, compound bevel,counterbore Angle:0°,30°,37.5°,Double 30°,37.5°+10° Size:90mm,150mm,200mm |

Insert style |

|

|

TOOL SLIDE

More Practical, More Ways, More Solutions

|

|

|

|

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Mini split frame pipe cutting and beveling machine

Mini split frame pipe cutting and beveling machine used by pipefitters and welders in weld preparation for industrial pipe. smartly designed, ability to split in half at the frame, easy to install on the pipe line.

Range for pipe OD 12.5-152.4mm

Heavy duty split frame pipe cutting and beveling machine

Aotai Heavy duty split frame machine, designed to cut, bevel, single point, counterbore and face on the Heavy wall pipe and flanges. Ideal for wide diameter range 12” in the one machine, and 8 models are available from 12” to 120”.

Range for Pipe OD 12"-120"

Standard split frame pipe cutting and beveling machine

Aotai Standard split frame machine, designed to cut, bevel, single point, counterbore and face on the pipe, tube and flanges. It is a portable pipe cutting and beveling machine tools of clamshell style. smartly designed, ability to split in half at the frame, easy to install on the pipe line.

Range for pipe OD 1"-48"