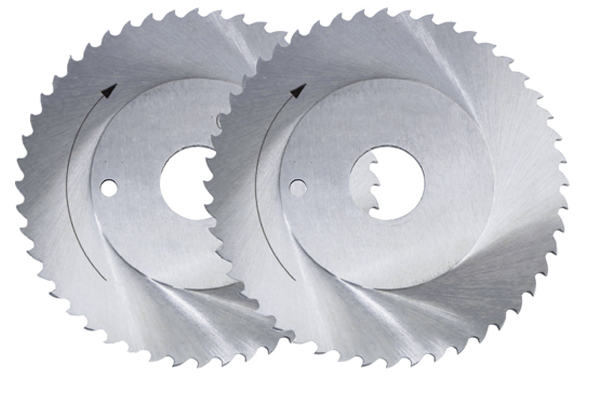

Attentions when using the HSS saw blade

Date: 2018-10-08 Clicks: 8125

Attentions when using the HSS saw blade

1.must be sure that the material has been fixed.

2.According to the material to set the cutting conditions

3.When putting the blades on the machines,cleaning the scobs on thefixtures is necessary,and then payattention to the direction of rotation,make sure that the blades is fixed.

4.At the beginnig and ending of the cutting,do not feed too fast,otherwise it may cause breakage and damage

5.Make full use of cutting oil(accotding to the material to choose the suitable cutting oil)

6.Throw away cutting machines and circulat sawing machines are totally different,must choose the right blade,do not mix.

Use of saw blade and attention

1.for a new HSSbkades,in order ot ensure it has a longer life,it is best to let circular saw machine and a new blade (to replace or re-sharpening HSS blade) running in process before cutting.reducing feed speed is very riecessaryin the first 10 minutes ,and then return to normal.

2.Feeding rates and cutting speed is depended onthe cutting sections and toughness of the material,for stainless steel which with high toughness and ‘tensile strength ,corresponding to reduce feed rates is very beneficial to improve the life of the saw blade ,if the section of the material is small,

3.If vou cut the same material and increase the feed speed ,you’d betterchoose the blade with fewer teeth.

4.The accurate cutting angle and effective teeth pitch is necessayr at any time when cutting any material,inorder to getting longer cutting life, to resharpening the blades should be on time and correct.

5.You can alse judge how about the cutting situation by obseriving the scobs:

A.if the scobs is small or in powderwhich means cutting pressure is too small

B.If the scobs is big and sofe which means cutting pressure is too big

C.If the scobs is spiral which means cutting siteuatioin is good

1.must be sure that the material has been fixed.

2.According to the material to set the cutting conditions

3.When putting the blades on the machines,cleaning the scobs on thefixtures is necessary,and then payattention to the direction of rotation,make sure that the blades is fixed.

4.At the beginnig and ending of the cutting,do not feed too fast,otherwise it may cause breakage and damage

5.Make full use of cutting oil(accotding to the material to choose the suitable cutting oil)

6.Throw away cutting machines and circulat sawing machines are totally different,must choose the right blade,do not mix.

Use of saw blade and attention

1.for a new HSSbkades,in order ot ensure it has a longer life,it is best to let circular saw machine and a new blade (to replace or re-sharpening HSS blade) running in process before cutting.reducing feed speed is very riecessaryin the first 10 minutes ,and then return to normal.

2.Feeding rates and cutting speed is depended onthe cutting sections and toughness of the material,for stainless steel which with high toughness and ‘tensile strength ,corresponding to reduce feed rates is very beneficial to improve the life of the saw blade ,if the section of the material is small,

3.If vou cut the same material and increase the feed speed ,you’d betterchoose the blade with fewer teeth.

4.The accurate cutting angle and effective teeth pitch is necessayr at any time when cutting any material,inorder to getting longer cutting life, to resharpening the blades should be on time and correct.

5.You can alse judge how about the cutting situation by obseriving the scobs:

A.if the scobs is small or in powderwhich means cutting pressure is too small

B.If the scobs is big and sofe which means cutting pressure is too big

C.If the scobs is spiral which means cutting siteuatioin is good

The key words of this article:Pipe cutting machine